Redefining Resilience: How Swiss Machining is Reshoring Critical U.S. Manufacturing

In an unassuming facility outside a Midwest industrial hub, a quiet revolution is underway. Here, at Falcon CNC Swiss, aerospace engineers in lab coats huddle around a digital display, not to examine a rocket component, but a spinal implant. The machine producing it—a nine-axis Swiss-type lathe—whirs with a purpose that belies its compact size, its tools moving with a synchronization that would impress a symphony conductor. This scene encapsulates a broader, underreported shift in American manufacturing: the strategic return of mission-critical precision work from overseas, driven not by political slogans, but by a powerful convergence of technological necessity, supply chain pragmatism, and relentless innovation in processes like Swiss machining.

For decades, the prevailing narrative was one of inevitable offshoring. Complex, labor-intensive parts for medical, aerospace, and defense applications followed a well-worn path to low-cost regions. Today, that calculus has fundamentally changed. The vulnerabilities exposed by global disruptions, coupled with breathtaking advances in precision manufacturing technology and a renewed focus on total cost of ownership, are driving a sophisticated form of reshoring. This isn’t about bringing back simple stamping or assembly; it’s about repatriating the most technically demanding, value-dense production—the very domain where Swiss machining excels.

The New Calculus: Why “Made Overseas” is No Longer the Default

The decision to manufacture a component is no longer a simple comparison of hourly labor rates. Modern supply chain analysis has evolved to account for a complex matrix of risk and cost factors that increasingly favor domestic precision production.

The Hidden Costs of Distance

A medical device company recently conducted a total cost analysis on a miniature titanium connector used in surgical robots. Produced overseas, the piece cost $12.50 per unit. Domestically, at a shop like Falcon CNC Swiss, the quoted price was $18.75. The offshore option appeared to win—until the company factored in the logistical reality. Eight-week lead times meant carrying $350,000 in inventory buffer stock. A single quality deviation in a shipment of 5,000 parts caused a six-week project delay, costing over $200,000 in lost clinical trial momentum. Intellectual property concerns required expensive legal safeguards. Suddenly, the true cost per part overseas soared to over $60, while the domestic cost, with its two-week lead time, zero inventory buffer, and collaborative engineering support, held firm. The equation had flipped.

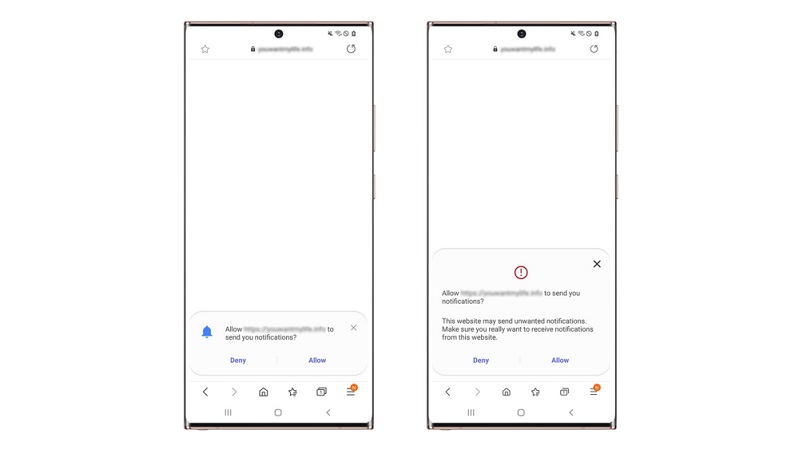

Today’s CNC Swiss machines are self-contained manufacturing cells. A single machine from the production floor at Falcon CNC Swiss can perform turning, milling, drilling, and tapping—often on all sides of a part—without ever releasing the workpiece.

Agility as a Strategic Imperative

In fields like aerospace and medical technology, design cycles are compressing. A prototype that once took 18 months must now be flight-ready in 9. This velocity is impossible with trans-Pacific shipping and 12-week machining queues. Swiss machining facilities embedded in the domestic innovation ecosystem act as rapid-response partners. A engineer can visit the shop floor in the morning to discuss a design-for-manufacturability tweak, and by afternoon, the updated program is running. This tight feedback loop, where designer and maker speak the same technical language and operate in the same time zone, accelerates innovation in ways a spreadsheet can never capture.

The Technology Enabler: How Swiss Machining Makes Reshoring Viable

The economic argument for reshoring only holds if domestic capabilities can match or exceed global standards. This is where the evolution of Swiss-type machining from a specialized craft to a technologically dominant process becomes critical.

From “Screw Machines” to Integrated Micro-Factories

The traditional image of a machinist manually feeding brass rods is obsolete. Today’s CNC Swiss machines are self-contained manufacturing cells. A single machine from Falcon’s production floor can perform turning, milling, drilling, and tapping—often on all sides of a part—without ever releasing the workpiece. This “done-in-one” philosophy eliminates the errors, handling damage, and queue times associated with moving parts between multiple machines. For a complex fuel system component with 17 features, what was once a 5-operation, 3-machine process across two weeks is now a 45-minute, unattended operation. This radical compression of process steps is a direct counter to the perceived labor-cost advantage overseas.

Digital Thread and Guaranteed Traceability

In regulated industries, provenance is everything. A jet engine bolt or a pacemaker component requires a complete digital birth certificate: material mill certs, tool wear data, in-process measurement logs, and final inspection reports. Advanced Swiss machining centers are data-generating engines. Every part produced at Falcon CNC Swiss is accompanied by a comprehensive data packet, accessible via a secure portal. This level of traceability is not just a compliance requirement; it’s a quality guarantee that builds immense trust. When a foreign supplier provides a paper certificate, a domestic provider offers a verifiable digital thread. In an age of liability and safety, this transparency is priceless.

The Human Factor: The Unsung Competitive Advantage

Beyond machines and metrics, the most compelling case for domestic precision manufacturing lies in its human capital. The skills developed in a high-mix, low-volume environment like a specialist Swiss machining shop are uniquely valuable.

- The Problem-Solving Craftsman-Engineer

The shop floor at a leading domestic precision manufacturer is not populated with machine minders. It’s staffed with hybrid professionals who can read a CAD model, understand metallurgy, program a CNC machine, operate a coordinate measuring machine, and diagnose a pneumatic system. This cross-disciplinary expertise is forged through necessity. When a batch of Inconel reacts unexpectedly, the team can’t wait 12 hours for an email reply from a foreign workshop. They must collaboratively troubleshoot material science, tool geometry, and coolant chemistry in real-time. This culture of embedded problem-solving leads to iterative process improvements that become proprietary knowledge—a form of institutional intelligence that cannot be easily replicated or exported. - Collaboration as an Innovation Engine

The relationship between a domestic manufacturer and its clients often evolves from transactional to strategic. Engineers from both sides co-locate to solve problems. This partnership yielded a breakthrough for a client developing a next-generation satellite communication component. The initial design called for an assembly of five separately machined beryllium-copper parts. A Falcon programming engineer, understanding the machine’s live-tooling capabilities, proposed a monolithic redesign. The new single-piece component was not only stronger and more reliable, but its production time dropped by 70%. This level of deep collaboration, where manufacturing expertise actively informs design, is the hallmark of a mature industrial ecosystem and a key driver of reshoring for R&D-intensive projects.

Case in Point: Securing Critical Medical Supply Chains

The COVID-19 pandemic laid bare the perils of concentrating medical device manufacturing offshore. Ventilator valves, diagnostic device components, and surgical tooling faced catastrophic shortages. In response, a conscious decoupling is occurring, with Swiss machining at its core.

A prominent example involves titanium trauma screws for orthopedic surgery. Previously sourced from a cluster of suppliers in Asia, production is now being intentionally diversified. A major medical OEM partnered with Falcon CNC Swiss to onshore a portion of this critical line. The challenge was not just replicating the part, but elevating its reliability. The domestic team implemented a 100% in-process optical inspection for thread form, a step deemed too costly in the high-volume offshore model. They also developed a proprietary post-processing technique that enhanced the bone-integrating surface texture, leading to better patient outcomes. The project’s success wasn’t measured just on cost-per-part, but on risk-per-part—a metric where domestic control scored decisively higher.

The Road Ahead: Building a Sustainable Precision Ecosystem

The reshoring of high-precision work is not a foregone conclusion; it’s a competitive opportunity that must be seized. Its sustainability hinges on several factors:

Investment in Advanced Capabilities: Continued investment in the latest multi-axis Swiss technology, additive-subtractive hybrid systems, and AI-driven process optimization is non-negotiable. Facilities must stay on the cutting edge to justify the cost differential.

Workforce Development: The pipeline of skilled machinist-programmers is the ecosystem’s lifeblood. Successful shops invest heavily in apprenticeship programs, often partnering with local technical colleges to build curricula that mirror real-world challenges.

Supply Chain Localization: True resilience requires a supporting network. The growth of domestic specialty steel providers, cutting tool manufacturers, and precision grinding services creates a virtuous cycle, making the entire domestic option more robust and responsive.

Conclusion: Precision as a Pillar of Sovereignty

The return of precision manufacturing to American shores is more than an economic trend; it is a strategic realignment. It recognizes that the ability to produce the most complex, reliable components for national defense, healthcare, and critical infrastructure is a form of modern sovereignty. It is a bet on the integrability of innovation, the value of velocity, and the undeniable worth of control.

This shift is being led not by giant conglomerates, but by agile, technologically sophisticated specialists. Companies like Falcon CNC Swiss are demonstrating that through advanced processes like Swiss machining, deep collaboration, and a relentless focus on total value, they can offer an alternative that is not just competitive, but compelling. They are proving that in the calculus of modern manufacturing, proximity, partnership, and proven reliability are the new currencies of advantage.

For industry leaders evaluating their supply chain strategy, the question is no longer “Can we afford to make it here?” but rather “Can we afford the risk of not having the option to make it here?” The answer, increasingly, is being written in the language of precision, cut into aerospace alloys and surgical-grade titanium, one ten-thousandth of an inch at a time.