How are Motherboards Made?

Motherboards are the backbone of any computer system, providing the necessary connections and power to keep everything running smoothly. But have you ever wondered how these crucial components are made? In this article by (Desktop Bold), I’ll be answering the question, “How are motherboards made?” and providing you with an in-depth look at the manufacturing process.

I’ll be discussing the materials and tools used, the different stages of production, and the quality control measures in place to ensure that each motherboard is up to industry standards. So, whether you’re a tech enthusiast or just curious about the inner workings of your computer, read on to find out everything you need to know about how motherboards are made.

What Is A Motherboard?

A motherboard is the main printed circuit board (PCB) in a computer or other electronic devices that connects and allows communication between various hardware components such as the CPU, memory, storage devices, graphics card, and other peripherals. It serves as a hub for all the internal connections in a computer and determines what types of components can be used, as well as how they interact with one another.

Motherboards come in various shapes and sizes, depending on the type of computer or device they are used in. They are typically made up of layers of copper traces and connections that carry electrical signals between the different components. In addition to this, motherboards also include various connectors, slots, and ports to allow for external connectivity, such as USB ports, Ethernet jacks, and audio jacks.

Overall, the motherboard is a critical component in a computer or electronic device, providing the foundation for all the other hardware components to work together seamlessly.

Related Article: How much Motherboard Cost?

What Is A Motherboard Made Of?

Motherboards are typically made of multiple layers of materials, including a fiberglass base layer known as the substrate, copper layers, and various components such as capacitors, resistors, and integrated circuits.

The substrate, also called the printed circuit board (PCB), is typically made of a type of fiberglass known as FR-4, which is coated in copper on both sides. The copper layers are etched to form circuits, traces, and connections that link the various components on the motherboard.

The copper layers are then covered in a layer of solder mask, which is a protective coating that prevents the copper from oxidizing and makes it easier to solder components onto the board. The motherboard may also be coated with a layer of silkscreen, which is a white layer that displays information such as component labels, logos, and other markings.

In addition to the substrate and copper layers, a motherboard also includes various electronic components such as capacitors, resistors, and integrated circuits. These components are soldered onto the board to provide the necessary functionality for the motherboard to operate.

Overall, the materials used in the construction of a motherboard are designed to provide a strong, durable, and reliable foundation for the computer’s hardware components to connect and communicate with each other.

Motherboard Manufacturing Process:

The manufacturing process for motherboards involves multiple steps and requires precision and attention to detail to ensure that the final product is of high quality. The following is a general overview of the motherboard manufacturing process:

Substrate preparation: The first step in manufacturing a motherboard is to prepare the substrate. This involves cleaning and polishing the fiberglass base layer to remove any impurities and ensure a smooth surface for the copper layer to be applied.

Copper application: Next, a layer of copper is applied to both sides of the substrate. This is done using a process called electroplating, where the substrate is submerged in a bath of chemicals and an electric current is used to deposit a layer of copper onto the surface.

Etching: Once the copper layer is applied, the next step is to etch away the excess copper to create the circuits and traces that will connect the various components on the motherboard. This is done using a chemical process that removes the unwanted copper and leaves behind the desired pattern.

Solder mask application: After the copper is etched, a layer of solder mask is applied to the board. This is a protective layer that covers the copper traces and prevents them from oxidizing or corroding over time.

Silkscreening: Once the solder mask is applied, a layer of silkscreen is added to the board. This is a white layer that displays information such as component labels, logos, and other markings.

Component assembly: The final step in the motherboard manufacturing process is to assemble the various components onto the board. This includes placing the capacitors, resistors, integrated circuits, and other electronic components onto the board and soldering them in place.

Overall, the motherboard manufacturing process is a complex and precise process that requires specialized equipment and expertise to create high-quality, reliable motherboards. Each step in the process is critical to ensuring that the final product meets the necessary specifications and performs as expected.

Parts Of A Motherboard:

A motherboard consists of many different parts, each of which plays a critical role in connecting and communicating with the various hardware components in a computer. Here are some of the main parts of a motherboard:

Socket: The socket is the area on the motherboard where the CPU (central processing unit) is installed. It provides the electrical connections that allow the CPU to communicate with other parts of the motherboard.

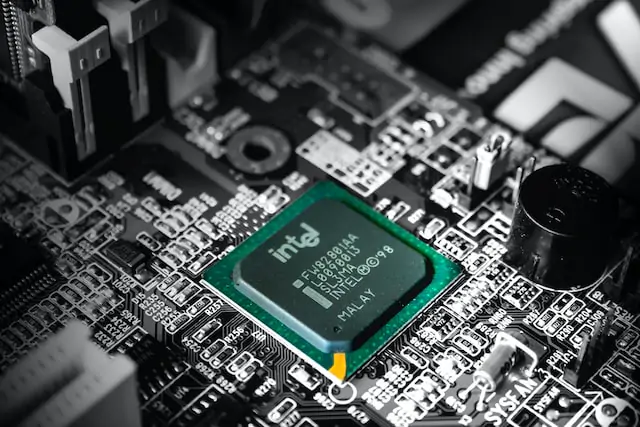

Chipset: The chipset is a collection of electronic components on the motherboard that manage the communication between the CPU, memory, storage, and other components. It plays a critical role in determining the performance and capabilities of the computer.

RAM slots: The RAM (random access memory) slots on the motherboard allow the installation of memory modules that provide temporary storage for data and program code.

Expansion slots: Expansion slots allow the installation of additional hardware components, such as graphics cards, sound cards, and network cards.

SATA connectors: SATA (serial advanced technology attachment) connectors allow the connection of storage devices, such as hard disk drives and solid-state drives.

BIOS chip: The BIOS (basic input/output system) chip on the motherboard contains the firmware that controls the startup and initialization process of the computer.

Power connectors: The power connectors on the motherboard allow the connection of the power supply unit, which provides the necessary electrical power to the various components in the computer.

USB headers: The USB (universal serial bus) headers on the motherboard allow the connection of USB ports for external devices, such as keyboards, mice, and thumb drives.

Overall, the parts of a motherboard work together to provide the necessary connectivity and communication between the various hardware components in a computer. Each component plays a critical role in ensuring that the computer operates as expected and provides the necessary performance and functionality for the user.

What are Northbridge and Southbridge Chip?

The Northbridge and Southbridge are two separate chips that used to be a common component of older motherboard designs. The Northbridge and Southbridge chips work together to manage the communication between the CPU, memory, expansion slots, and other components of the computer.

The Northbridge chip is responsible for connecting the CPU to high-speed components, such as the memory and graphics card. It handles the communication between the CPU and the memory, and provides the interface for the graphics card to connect to the motherboard.

The Northbridge chip is also responsible for managing the flow of data between the CPU and other high-speed components, such as the hard disk drives and solid-state drives.

The Southbridge chip, on the other hand, is responsible for connecting the CPU to slower components, such as the USB ports, network card, and other peripheral devices. It handles the communication between the CPU and the slower components, and provides the interface for connecting devices to the motherboard.

While Northbridge and Southbridge chips used to be a common component of older motherboard designs, they have been largely replaced by a single chipset that integrates both functions. This has led to simpler and more efficient motherboard designs, with improved performance and capabilities.

What Does It Take To Be A Good Motherboard?

To be considered a good motherboard, a number of factors need to be taken into consideration. Here are some of the key characteristics that contribute to a high-quality motherboard:

Compatibility: A good motherboard should be compatible with the hardware components it is designed to work with, including the CPU, memory, and storage devices. Compatibility issues can lead to problems with performance, stability, and reliability.

Performance: A good motherboard should provide strong and reliable performance, with efficient communication between the CPU, memory, and other components. The motherboard should be able to support high-speed components and provide the necessary bandwidth to keep up with demanding workloads.

Reliability: A good motherboard should be reliable and stable, with few issues or problems. It should be able to handle heavy use and provide consistent performance over time.

Features: A good motherboard should provide a range of features that are useful and practical for the intended use case. This may include support for high-speed memory, expansion slots, multiple USB ports, and other features that improve the functionality and convenience of the motherboard.

Durability: A good motherboard should be well-built and able to withstand regular use and handling. The components and connections on the motherboard should be designed to last and resist damage from wear and tear.

Cost: A good motherboard should provide good value for its price, with a balance between performance, features, and cost. It should be competitively priced and offer good performance for the intended use case.

Overall, a good motherboard should provide reliable and efficient performance, with a range of features that are useful and practical for the intended use case. It should be well-built and durable, with good compatibility and a reasonable price point.

Conclusion:

In conclusion, the manufacturing process of motherboards involves a complex and precise set of steps that are crucial for creating a high-quality product. From designing the layout and schematics to printing the layers and assembling the components, each step is carefully planned and executed to ensure that the motherboard functions as intended. Understanding how motherboards are made can help users appreciate the complexity and craftsmanship involved in creating these essential components of modern computers. By being aware of the manufacturing process, users can also make more informed decisions about purchasing and using motherboards in their own computing setups.